A tool case is a portable container created to store, organize, and safeguard tools while facilitating simple accessibility. One can use common tool cases when working on a project. For specific and unusual uses, bespoke and custom toolboxes are also offered. For delicate instruments and electrical devices, foam inserts that fit the design of the tools, for instance, provide additional protection. Many tool cases come with a strong outer shell that closes to guard tools against air pollutants, water damage, harmful liquids, and dirt. There are many different sizes of tool bags to suit every use, including portable and mobile ones. Each is created to meet the needs and demands of the user. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases.

Royal Case Company, as premium carrying case suppliers, designs carrying cases based on industry specifications, including athletics, industrial and law enforcement. Through versatility and innovation, Royal Case Company offers a diverse carrying case product line including computer cases, plastic cases, aluminum cases, instrument cases, transit cases, custom cases, shipping cases and tool cases.

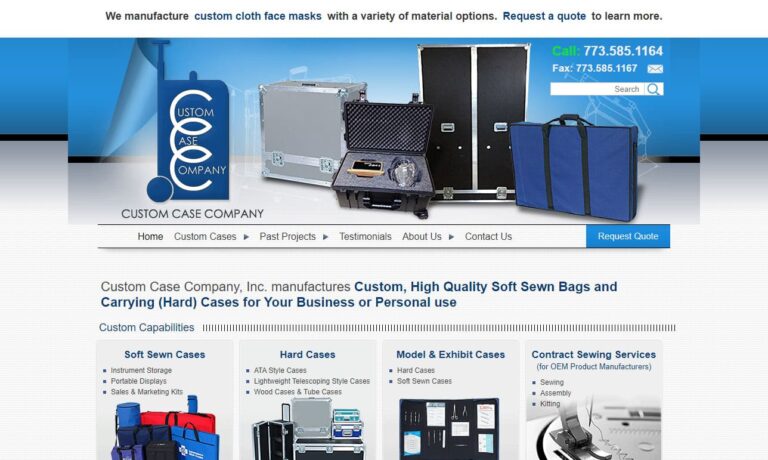

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

Custom Case Group (CCG) partners with Pelican, Anvil, Zarges, and Wilson to create custom cases for the aerospace, equipment, fire/rescue, hazmat, industrial, medical, military, OEM, oil and gas, shipping, and trade show industries. We also feature DroneHangar, a line of custom cases for drones and UAV/unmanned vehicles. Our engineers specialize in custom rackmount, carrying and shipping cases....

SBC Case Industries has provided carrying case solutions for over 22 years, and has proven to be elite carrying case manufacturers. SBC Case provides premium carrying cases to customers such as Home Depot and SaskTel. SBC Case is one of few carrying case companies that provide such a wide carrying case product range at a single source, including custom carrying cases, soft cases and hard cases.

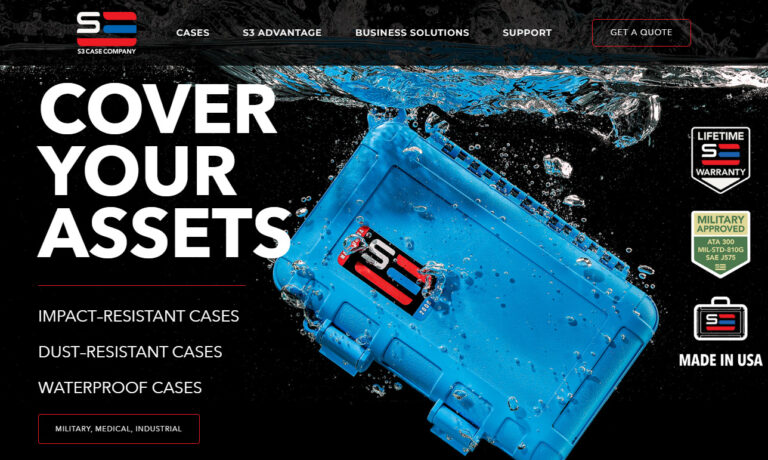

S3 manufactures waterproof, crushproof cases and participates in the sale of HPRC cases of Italy. All S3 cases are made in the U.S. with stainless steel pins and high impact ABS. All cases carry a lifetime warranty and are virtually indestructible. Give us a call today!

More Tool Case Manufacturers

Materials in Tool Casing Production

Due to the harsh environmental conditions they encounter in various corporate, industrial, engineering, and other applications, toolboxes must be protected from shock, vibration, and factors including dampness, salt spray, dust, and water immersion. Tool cases are frequently made of aluminum, linear low-density polyethylene, high-density polyethylene (HDPE), fiberglass reinforced polyester (FRP), carbon fiber, and rotationally molded polyethylene (LLDPE). Some instruments that require extra protection from the elements or damage may be kept in specialized toolboxes to suit specific requirements. Some tool bags, for instance, include zippered closures to protect from outside elements.

Types of Tool Cases

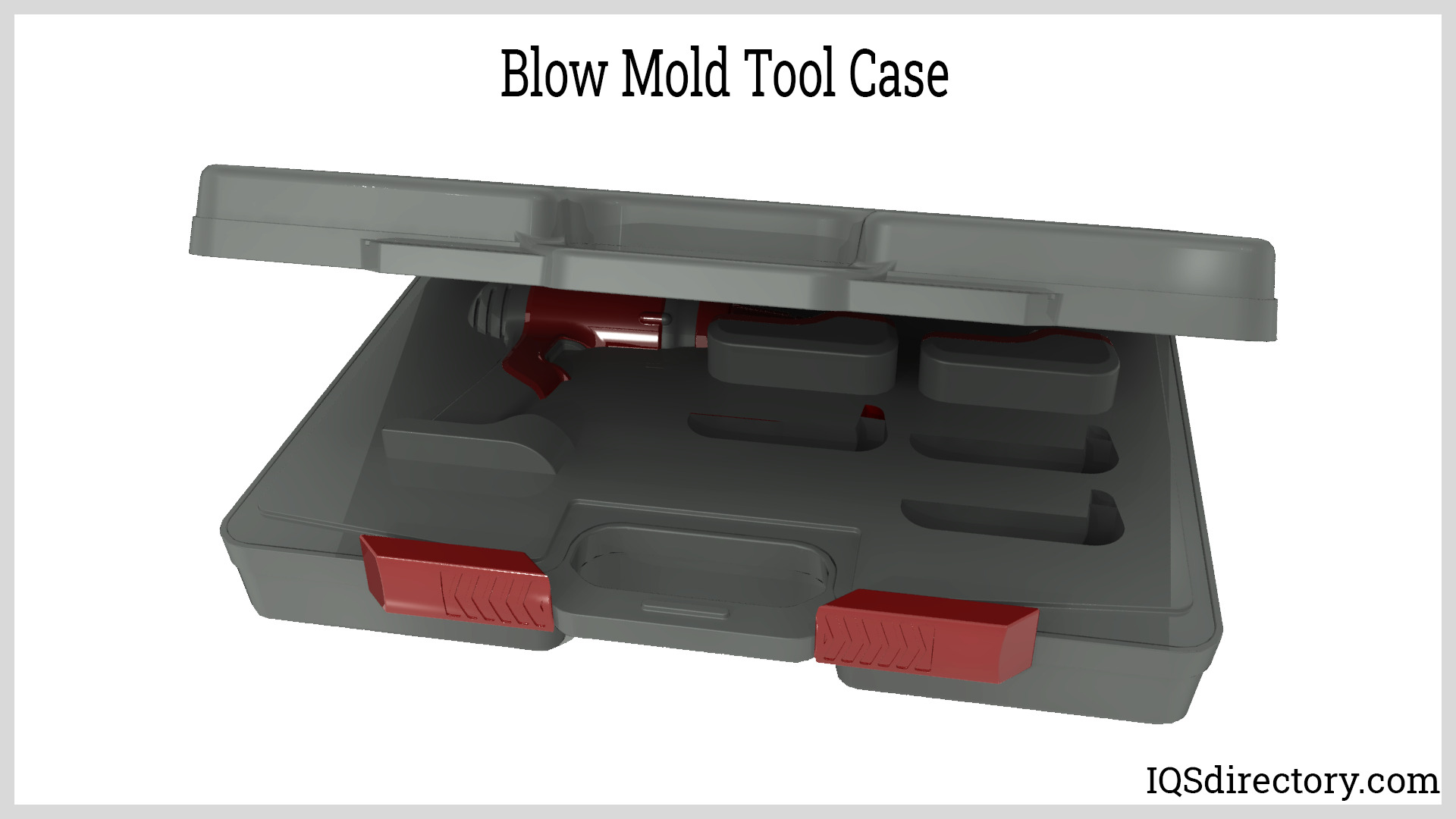

Blow Molded

Blow-molded tool cases are an increasingly popular tool container made specifically to hold electric instruments securely and protectively in place. A single electric tool or sets of similar tools created for a particular application are frequently sold in multiple blow-molded toolboxes. Blow-molded tool covers provide excellent protection for tools, particularly technological ones, thanks to their solid and long-lasting design. The contoured blow molding firmly holds them in place to keep the tools from causing damage to one another. This tool container is appropriate for tools with multiple pieces, such as socket sets, screwdriver sets, and testing tools and instruments.

One of the more practical tool cases among the many available ones is pocket tool cases. They can carry goods that get lost in a larger tool kit, such as cell phones, fine instruments, tiny parts, and accessories. Additionally, pocket tool cases can be slung from a worker's arm, hung from their shirt pocket, or hung from their belt. Pliers, lighting devices, screwdrivers, small tools, and sharp-pointed tools are examples of equipment small enough to fit in a pocket toolbox.

Briefcase

Tool briefcases can be perplexing because they resemble business briefcases exactly. When technicians need to visit a customer location but want to avoid interfering with office procedures, they should use this toolbox. Briefcase tool cases are broader than the typical briefcase and built of a particularly robust material that allows them to withstand severe handling. Similar to the typical briefcase, tool briefcases come in various designs to suit the user's demands. Tool briefcases feature many compartments, tool boards, and a sectioned-off area for paperwork and instructions.

Rolling

Rolling cases may be the most resilient among the numerous forms of toolboxes. High-density polyethylene is typically used in their construction, which increases their toughness and lifetime. Additionally, there are a variety of interiors for rolling toolboxes, from ones that feature foam shapes for additional tool protection to ones with pockets for tool placement and part placement. Rolling tool cases make transporting tools and equipment easy, especially when the items transported are large or heavy. The majority of rolling toolboxes incorporate ribbing for added rigidity and strength.

Foam Insert

To keep their calibration, foam insert tool cases, frequently used with breakable tools, must be securely held. Although this tool bag can hold any tool, technicians who use their equipment to obtain readings and make technical changes frequently use them. Foam inserts can be carefully and accurately form-fitted by toolbox manufacturers to any tool's shape and arrangement. Some tool cases feature foam that is colored to make it simpler to view the assortment of tools. Additionally, this capability can be used to catalog and organize tools.

Fabrication of Tool Cases

The material's performance and, consequently, the case are influenced by the fabrication processes used to make tool cases, particularly in strength, shock absorption, and fracture resistance. Many general tool cases have panels made of high-density polyethylene or fiberglass-reinforced polyester that are strengthened with extruded aluminum or steel hardware. Before being connected to the matrix, a strong yet relatively weak plastic surface, the fibers of FRP plastics must first be woven, knit, braided, or stitched together. In the composite molding process, the two materials combine to create a very stiff and strong substance that is then compressed or heated into the desired shape. Like dry molding, wet molding involves shaping a form while reinforcing the matrix with fibers. Extruded aluminum, produced when aluminum bars or rods are pressed through a die to create the correct cross-section, is often used to make the interior frames that safely hold the tools and equipment. They are joined by welding and put inside the tool container to give structure and stability. Shock mounts can be installed on large or delicate equipment to safeguard the frame by deflecting vibrational energy away from the tools.

Choosing the Correct Tool Cases Manufacturer

To make sure you have the most beneficial outcome when purchasing Tool Cases from a Tool Cases Company, it is important to compare at least 6 Suppliers using our list of Tool Cases companies. Each Tool Cases Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Tool Cases business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Tool Cases companies with the same quote.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

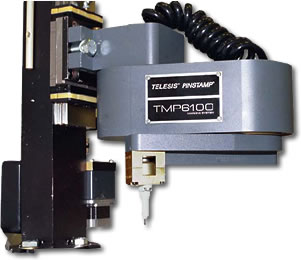

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services