Aluminum cases also provide EMI and RFI shielding for sensitive electronic equipment. Sales and tradeshow professionals use custom-sized aluminum trade show cases to store and display products and equipment. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases.

Royal Case Company, as premium carrying case suppliers, designs carrying cases based on industry specifications, including athletics, industrial and law enforcement. Through versatility and innovation, Royal Case Company offers a diverse carrying case product line including computer cases, plastic cases, aluminum cases, instrument cases, transit cases, custom cases, shipping cases and tool cases.

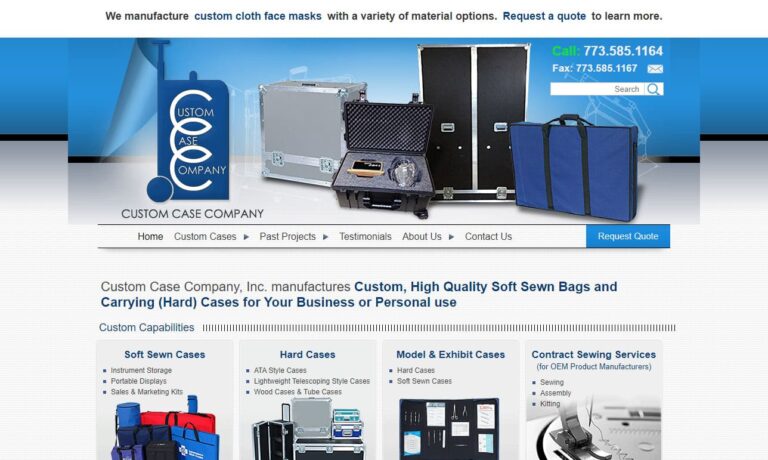

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

Custom Case Group (CCG) partners with Pelican, Anvil, Zarges, and Wilson to create custom cases for the aerospace, equipment, fire/rescue, hazmat, industrial, medical, military, OEM, oil and gas, shipping, and trade show industries. We also feature DroneHangar, a line of custom cases for drones and UAV/unmanned vehicles. Our engineers specialize in custom rackmount, carrying and shipping cases....

SBC Case Industries has provided carrying case solutions for over 22 years, and has proven to be elite carrying case manufacturers. SBC Case provides premium carrying cases to customers such as Home Depot and SaskTel. SBC Case is one of few carrying case companies that provide such a wide carrying case product range at a single source, including custom carrying cases, soft cases and hard cases.

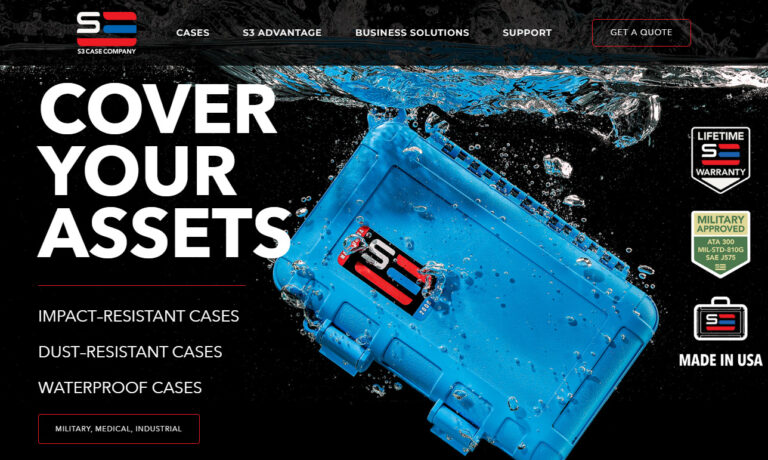

S3 manufactures waterproof, crushproof cases and participates in the sale of HPRC cases of Italy. All S3 cases are made in the U.S. with stainless steel pins and high impact ABS. All cases carry a lifetime warranty and are virtually indestructible. Give us a call today!

More Aluminum Case Manufacturers

Custom cut foam inserts and custom decorative silk screening are often included in aluminum case manufacturers' services. Custom fabrication of aluminum cases is vital for many OEM and industrial electronics applications that require equipment to be built directly into a case. The electronic, digital, video and photography industries use aluminum cases as storage and transit cases for sensitive equipment; the benefits of aluminum make these cases excellent shipping, transit and storage solutions for industrial, firearm and hunting equipment, computers and video games, motorcycle storage attachments and craftsmen hobby boxes as well as many other applications.

Aluminum cases are fabricated from sheets of metal that have been fastened together onto a metal frame. Because of the pressure from use, many aluminum cases have reinforced corners that also help protect the case from wear and tear. Manufacturing sheet metal begins with raw materials that are heated together until uniform. The metal is formed into large rough shapes and, once cool, the smelted aluminum goes through a series of rollers that reduce the thickness of the aluminum.

Other processes such as cutting, perforating, spinning, press brake forming, stamping, bending, ironing or wheeling may also be performed, depending on the requirements of the customer. The sheets are then fastened onto a frame of extruded aluminum bars or pipes. Extrusion is a process where a solid bar or rod of aluminum is forced through a die that removes the negative space to create a certain cross section. The parts may also be welded together.

A finish is applied, if desired. Other additional features may include heavy duty swivel casters, twist latches, spring loaded handles, rubber gaskets around the doors for water resistance, recessed latches to meet military standards, lugs for secure stacking, shock mounts, enhanced and fortified aluminum framing, buckles, straps, tracks for easy stacking or many other options.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

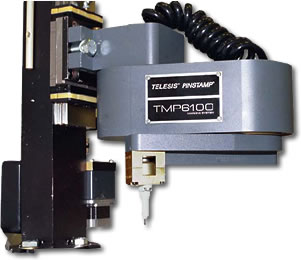

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services